Hydraulic double roll crusher

Product Introduction

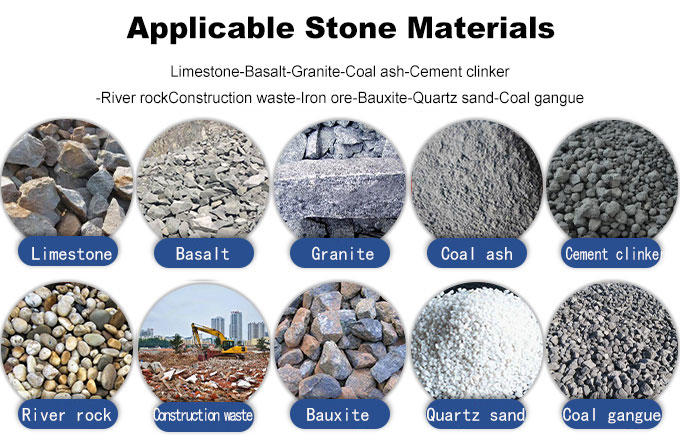

Hydraulic double-roll crusher is a kind of double-roll crusher. It is named because its main crushing part is composed of two rollers. The roller crusher is simple in structure and can be used for medium and fine crushing of medium-hard and soft ores. The roller crusher has many advantages such as finer crushing particles, larger capacity, simple operation, long service life, adjustable discharge particle sizes, and wide applications.

Application

The hydraulic double-roll crusher is suitable for the medium and fine crushing of solid materials with a compressive strength lower than 300Mpa and a moisture content less than 35%, such as iron ore, quartz stone, potassium (sodium) feldspar, limestone, river pebble, and metal Silicon, barite, basalt, granite, steel slag, cement clinker, construction waste (concrete), shale, quicklime, coal, coke, clay, bentonite, chemical raw materials, etc. It can be widely used in mining, thermal power, cement ceramics, metallurgy, chemical industry, building materials and other industries. It has many advantages such as low operating cost, low moisture requirement, reliable performance, low power consumption, low dust and low noise.

Working principle

The roller crusher mainly uses two sets of independently driven rollers to break materials through the extrusion and grinding force generated by relative rotation. The material falls between the two rollers through the feed port, and the finished product falls naturally after being crushed by the pair of rollers. When encountering hard or unbreakable materials, the roller can automatically retreat under the action of the hydraulic cylinder or spring, so that the gap between the two rollers increases, and the hard or unbreakable materials naturally fall to ensure that the machine is not damaged. By adjusting the pressure of the hydraulic cylinder or spring, the pressure between the two rollers increases or decreases to control the size of the finished product, and the greater the pressure, the smaller the finished product.

Advantages:

• Compact structure • Efficient and energy-saving

• Large crushing ratio • Good crushing effect

• Upgraded system • Automatic hydraulic system

• Thickened roller skin • Long service life

• Hydraulic-spring integration, balanced flashback protection

• The discharging granule is full, the gradation is reasonable, and the powder content in the finished product is low.

• The hydraulic roller crusher has a low loss rate of wear parts, and the roller sleeve is made of manganese-chromium alloy steel with a long average service life.

Model parameter

|

Model |

Roll diameter |

Roll surface width |

Feed size |

Discharge size |

Capacity |

Power |

|

2PG400×250 |

400 |

250 |

<35 |

≤2-8(adjustable) |

2-10 |

5.5x2 |

|

2PG400×400 |

400 |

400 |

<35 |

≤2-8(adjustable) |

5-15 |

7.5x2 |

|

2PG610×400 |

600 |

400 |

<40 |

≤2-8(adjustable) |

10-20 |

15x2 |

|

2PG750×500 |

750 |

500 |

<40 |

≤2-8(adjustable) |

20-35 |

18.5x2 |

|

2PGY800×600 |

800 |

600 |

<40 |

≤2-8(adjustable) |

25-40 |

22x2 |

|

2PGY1000×800 |

1000 |

800 |

<50 |

≤2-8(adjustable) |

45-60 |

37x2 |

|

2PGY1200×800 |

1200 |

800 |

<60 |

≤2-8(adjustable) |

50-100 |

75x2 |

|

2PGY1500×800 |

1500 |

800 |

<80 |

≤2-8(adjustable) |

90-140 |

132x2 |

|

2PGY1500×1000 |

1500 |

1000 |

<80 |

≤2-8(adjustable) |

120-180 |

132x2 |

|

2PGY1800×1000 |

1800 |

1000 |

<100 |

≤2-8(adjustable) |

160-240 |

220x2 |

Note: The equipment is constantly updated and improved, if the model parameters change, please refer to the contact.